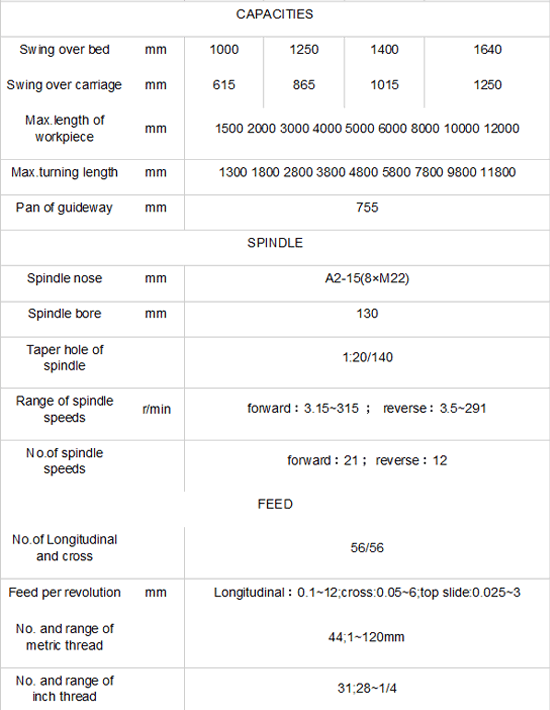

This series of lathe machine bed is the overall box-shaped structure, adopts high standard cast iron one molding casting, after the second aging treatment, it has the feature of stable performance; guide way width (755mm), good rigidity, anti-vibration ability; spindle bore is 130mm, strong rigidity of headstock, adapting to heavy cutting. Automatic segmentation speed change controlled by the M code, steeples speed within segment controlled by the S code, achieving steeples speed and constant linear cutting. The X-direction and Z-direction use the precision grinding grade ball screw, ensured a high processing accuracy, positioning accuracy and accuracy of retention. Longitudinal (Z) Feeding: for the distance between centers from 1000mm-5000mm specifications: AC servo motor that installed on the left side of the feeding box drives the ball screw via high precision planetary reducer, longer than 6000mm is the rack and pinion structure. Equipped with 4-station vertical electric turret, but also according to their customers’ needs 6-station horizontal electric turret and 8-position horizontal electric turret can be chosen. Tailstock structure is strong, which can perform heavy cutting, it can also be chosen electric tailstock to achieve automatic rapid movement and improve efficiency. Spindle motor adoptsα50-6000ip servo motor or 22kw high-power AC variable frequency main motor with frequency converter, the output is large and variable speed range is big. Equipped with Ф1000mm standard manual four-jaw chuck, but also different types of manual, pneumatic and hydraulic three-jaw or four-jaw chuck can be chosen according to customers’ need. The lathe machine axis-X and Z ball screw have taken protective measures equipped with emergency stop safety button, when the lathe machine suddenly encountered a sudden power failure or other failures, due to the special design of the control circuit, it can be self-protection to ensure that the lathe machine and staff safety.

CNC system uses the most well-known international control system. Programs and parameter can be transferred through manual writer and standard communication interface. Axis –X and Z are controlled at the same time, it has a straight line, arc and thread interpolation and a variety of other fixed cycle and other functions, the minimum resolution is 0.001mm.

This series of lathe machine is a popular CNC lathe developed according to the latest development trend of CNC lathes in the international market. They are used widely, flexible operation, suitable for processing all kinds of complex shapes of shafts, sets, disk parts, such as turning inside and outside cylindrical surface, conical surface, circular surface, end face, grooving, chamfer, threading, Especially for multi-species, small batch of turns processing, process adaptability, high processing efficiency, low scrap rate, good product consistency, easy programming, simple operation, reducing the technical requirements of workers, it is the ideal medium mechanical processing equipment.

Don’t miss our future updates! Get Subscribed Today!

Let's Connect