*The series deep hole drilling and boring machine adopts the double rectangle guideway on the bed body, which is treated by hardening technology and has the excellent wear-resistance.

*The protection device is installed around the machine to avoid oil splash and leakage.

*The feeding system and oil feeder adopt servo motor control and gear-rack transmission to assure the safety of the tool and the workpiece, the machine is easily operated and has the good rigidity.

*The spindle motor uses AC variable frequency motor with stepless speed regulation.

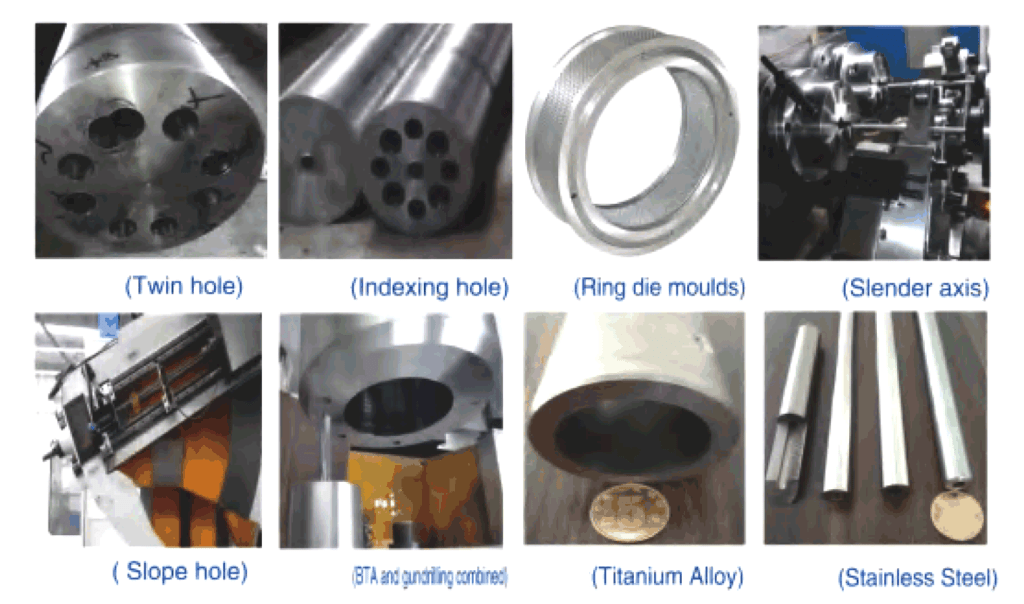

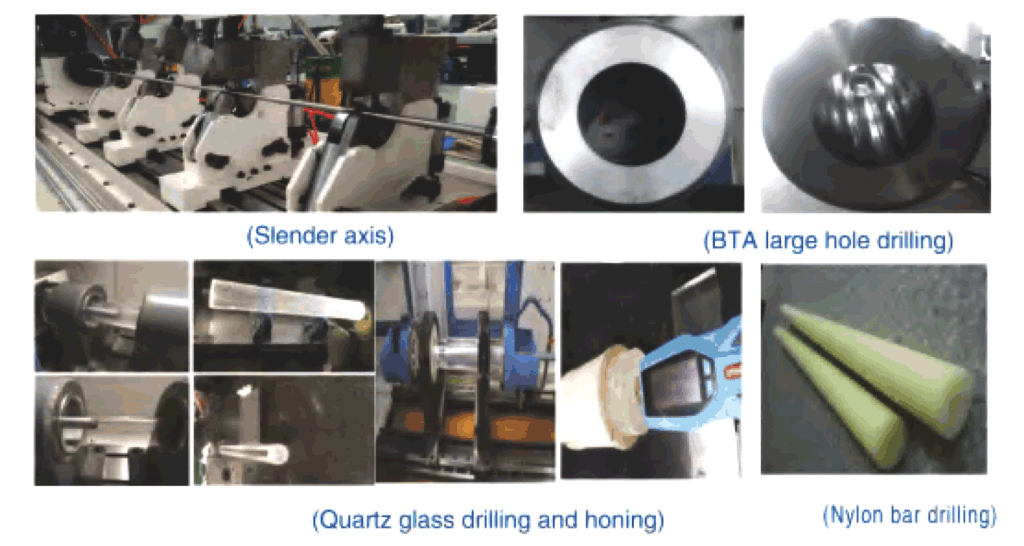

*It is applicable to the process of drilling and boring. When drilling the machine adopts internal chip- removal (BTA type), the cutting oil is supplied by oil feeder to cutting area, the chip is discharged through the inner hole of drilling bar and is collected into the chip container located in the back part of the machine.

*The machine is equipped with high efficient compound tool, the skiving roller burnishing tool can be expanded and retracted automatically, it can achieve high efficient processing for oil cylinder production.

Don’t miss our future updates! Get Subscribed Today!

Let's Connect