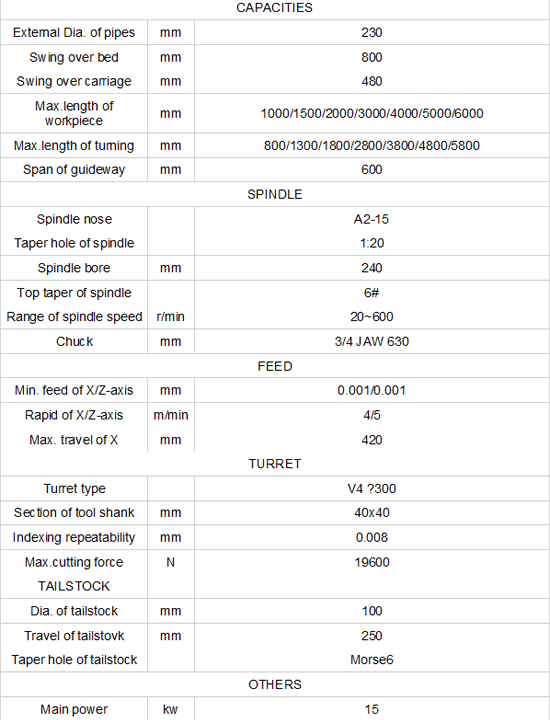

This series of lathe machine beds is an overall structure (6000 long is two pieces ), uses high standard cast iron one molding casting, and a guideway width is 600mm. After the second aging treatment, it has the feature of stable performance; Anti-vibration ability. The spindle bore diameter is 240mm, pipe diameter that can be processed is 230mm. The spindle is supported by two-point with precision heavy load bearings. A step-less segmentation speed controlled by the M code, step-less speed step-segment controlled by the S code, achieving steeples speed and constant linear cutting. The X-direction and Z-direction use the precision grinding grade ball screw, ensured a high processing accuraensuringitioning accuracy and accuracy of retention.

Longitudinal (Z) Feeding: distance between centers for 1000 mm-1500 mm: the AC servo motor mounted on the left side of the feed box is connected directly to the longitudinal ball screw via a coupling. 2000 mm-3000 mm: AC servo motor mounted on the left side of the feed box plus reduction gears (1:3) drive the ball screw directly via a coupling.

4000 mm-6000 mm: AC servo motor mounted on the left side of the feed box plus reduction gears (1:4) drive the ball screw directly via a coupling.

Horizontal (X-direction) Feeding: the AC servo motor mounted on the back of the bed saddle is connected to a horizontal ball screw via coupling.

Before delivery all lathe machines should be tested by the British RENISHAW laser detector for dynamic accuracy detection and compensation, so the lathe machine has a high positioning accuracy and repeats positioning accuracy. All the lathe machines are equipped with an electric turret, free lifting, tool change quickly and easily, there are vertical 4 and 6 stations and horizontal 6 stations, and another electric turret to choose from. The main motor is a 15kw high-power frequency, the main man. Equipped with one Ф630 manual three-jaw self-centering chuck and one Ф630 manual four-jaw independent chuck, the CNC system uses the internationally renowned FANUC 0i, SIEMENS, AC servo control system. The lathe machine adopts semi-closed protection or fully enclosed protection, equipped with emergency stop safety button, when the lathe machine suddenly encountered a sudden power failure or other failures, due to the special design of the control circuit, it can be self-protection to ensure that the lathe machine and personnel safety. The operator panel is about 1500mm from the ground, highly moderate, ergonomic, pleasant, and easy to operate and understand the operation of the machine.

This series of lathe machines is mainly developed for the turning of oil field pipe thread, it is not only suitable for all kinds of pipe thread turning but also can be used for ordinary CNC lathe, suitable for processing complex shapes of the shaft, sets, disk parts, such as turning inside and outside cylindrical surface, conical surface, circular surface, end face, chamfer. Especially for a multi-species, small batch of turning processing, process adaptability, high processing efficiency, low scrap rate, good product consistency, easy programming, simple operation, and reducing the technical requirements of workers, it is the ideal medium mechanical processing equipment

Don’t miss our future updates! Get Subscribed Today!

Let's Connect